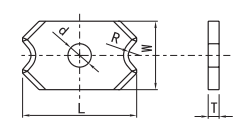

Izikhala ze-Carbide zokuphrinta – 20X12X2

• Ingasetshenziselwa ukwakheka okuhlukile embonini yezinkuni.

• Imiphetho ebukhali enomthelela nokuqina kokugqoka

• Icubungula ngokushesha kune-HSS namanye amathuluzi wensimbi

Izikhala ezahlukahlukene zokuphrinta ziyatholakala Osayizi abenziwe ngokwezifiso kanye nokuma kuyamukelwa, futhi.

| L | UW | T | d | R |

| 20 | 12 | 2 | 4 | 1 |

| 20 | 12 | 2 | 4 | 2 |

| 20 | 12 | 2 | 4 | 3 |

| 20 | 12 | 2 | 4 | 2.5 |

| 20 | 12 | 2 | 4 | 4 |

| 20 | 12 | 2 | 4 | 5 |

| 20 | 17.5 | 2 | 4.5 | 3 |

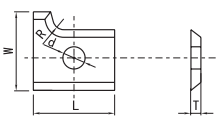

| L | UW | T | d | R |

| 12 | 14.5 | 2 | 4 | 2 |

| 19.6 | 15.2 | 2 | 4 | 2 |

| 12 | 14.5 | 2 | 4 | 2 |

| 12 | 14.5 | 2 | 4 | 2 |

| 20 | 14 | 1.5 | 4.1 | 1.5 |

| 20 | 14 | 1.5 | 4.1 | 1.5 |

| 19.6 | 15.2 | 2 | 4 | 2 |

Izikhala ze-carbide zokuphrinta ziye zagaywa yonke imiphetho, Ingasetshenziswa kwifenisha ehlukile nasembonini yezinkuni.

|

Ibanga |

I-ISO |

Co% |

Ubulukhuni |

Amandla okugoba |

ukusebenza |

|

HCK10UF |

I-K05-K10 |

6.0 |

92.5HRA |

2060N / mm² |

I-tungsten carbide powder yangempela. It has omuhle bafake ukumelana. |

|

HCK30UF |

I-K20 |

10.0 |

91.5HRA |

2520N / mm² |

Isikhathi esiningi, amathuluzi we-carbide aqinisiwe azonikeza indawo engcono ezingxenyeni futhi ingacutshungulwa ngokushesha kune-HSS namanye amathuluzi ensimbi. Uma kuqhathaniswa namathuluzi wensimbi asheshayo ajwayelekile, amathuluzi we-carbide aqinisiwe angamelana namazinga okushisa aphezulu kusixhumi esibonakalayo se-workpiece (lesi yisona sizathu esiyinhloko sokucubungula okusheshayo). I-carbide ehlanganisiwe imvamisa ukumelana nokugqokwa kunezinye izinto ezifana nensimbi eshesha kakhulu ekukhiqizeni ngobuningi nokukhiqiza kahle, futhi inempilo ende. Lokhu kuyiqiniso futhi ekusetshenzisweni kwezinkuni nasekucutshungweni kwepulasitiki. Izimboni ze-carbide blade, ezibizwa nangokuthi ukufakwa kwe-carbide zivame ukuthuthukisa ukuphela kwento yokusebenza.

Uma udinga amasampula noma uneminye imibuzo xhumana nathi manje