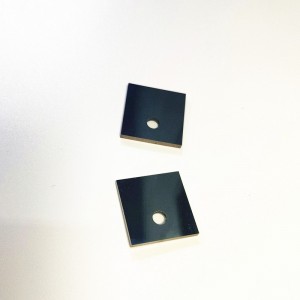

Carbide blanks for profiling–20X12X2

• It can be used for different shape in woodworking industry.

• Sharp edges with impact and wear-resistance

• It process faster than HSS and other steel tools

A wide range of blanks for profiling is available Customized sizes and shape is accepted, too.

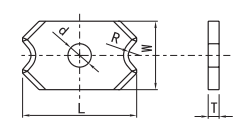

| L | W | T | d | R |

| 20 | 12 | 2 | 4 | 1 |

| 20 | 12 | 2 | 4 | 2 |

| 20 | 12 | 2 | 4 | 3 |

| 20 | 12 | 2 | 4 | 2.5 |

| 20 | 12 | 2 | 4 | 4 |

| 20 | 12 | 2 | 4 | 5 |

| 20 | 17.5 | 2 | 4.5 | 3 |

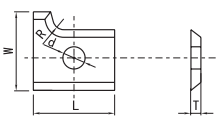

| L | W | T | d | R |

| 12 | 14.5 | 2 | 4 | 2 |

| 19.6 | 15.2 | 2 | 4 | 2 |

| 12 | 14.5 | 2 | 4 | 2 |

| 12 | 14.5 | 2 | 4 | 2 |

| 20 | 14 | 1.5 | 4.1 | 1.5 |

| 20 | 14 | 1.5 | 4.1 | 1.5 |

| 19.6 | 15.2 | 2 | 4 | 2 |

The carbide blanks for profiling have been grind all edges, It can be used on different furniture and woodworking industry.

|

Grade |

ISO |

Co% |

Hardness |

Bending Strength |

performance |

|

HCK10UF |

K05-K10 |

6.0 |

92.5HRA |

2060N/mm² |

Original tungsten carbide powder. It has excellent wear resistance. |

|

HCK30UF |

K20 |

10.0 |

91.5HRA |

2520N/mm² |

Most of the time, cemented carbide tools will provide a better surface finish on the parts and can be processed faster than HSS and other steel tools. Compared with standard high-speed steel tools, cemented carbide tools can withstand higher temperatures at the workpiece interface (this is the main reason for faster processing). Cemented carbide is usually more wear-resistant than other materials such as high-speed steel in mass production and efficient production, and has a longer service life. This is also true in wood processing and plastic processing. Industrial carbide blades, also called carbide inserts often improve the surface finish of the workpiece.

If you need samples or have further questions just contact us now